SpecialCoat

The specialist for heavy metal. The clean method that provides temporary corrosion protection for your pipes. Alternatively, to only simply coat your pipes, tubes or chains perfectly.

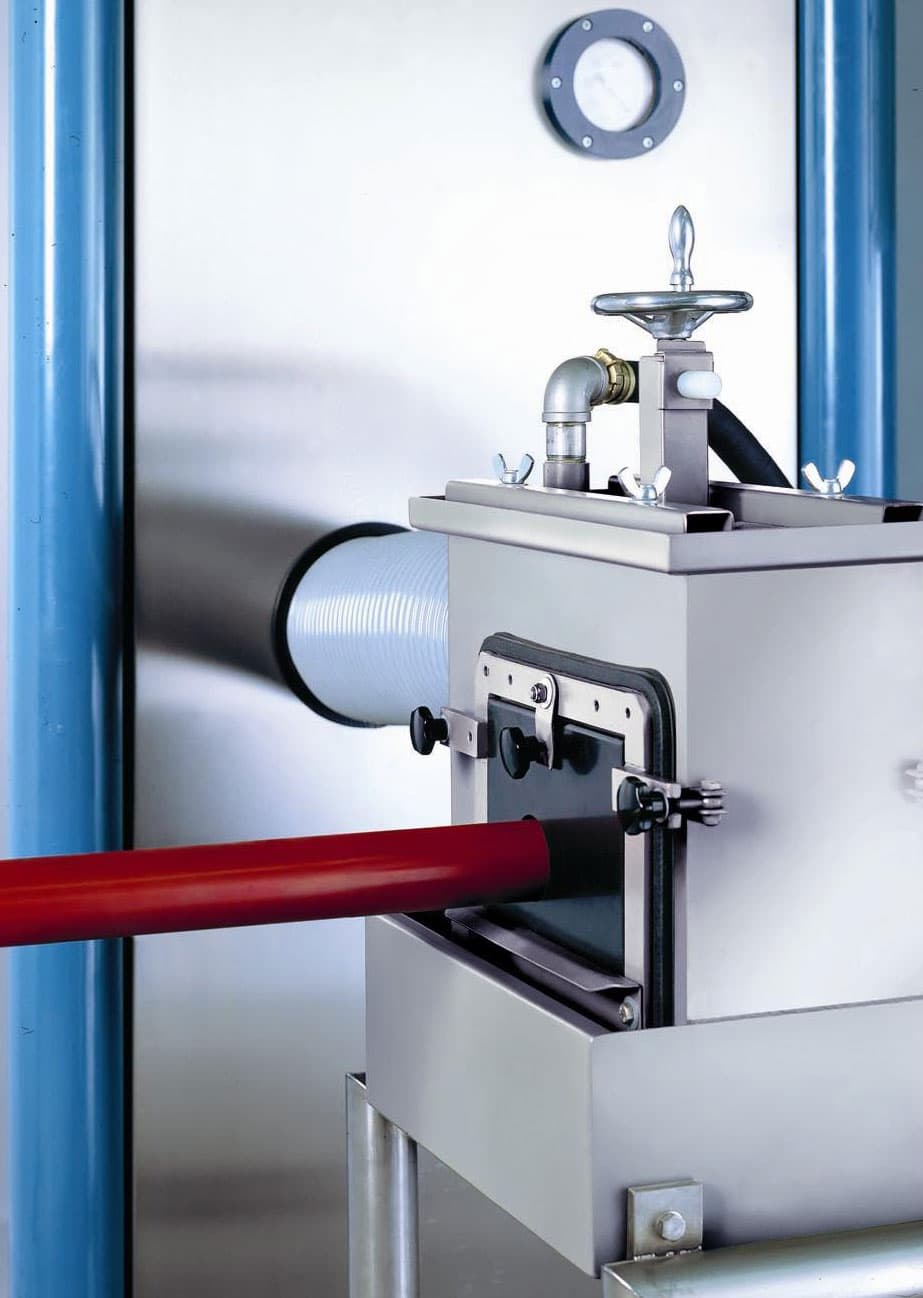

Integrated as a separate surface application or into a production line: the VACUMAT SpecialCoat is characterised by its compactness and efficiency.

Scope of application

- Pipes

- Tubes

- Chains

- Coils

- Knife edges

- All lengthwise directed workpieces or strand cast products that need to be coated within a production process

Performance features

- Even and all-round coating of pipes, tubes, and chains in one pass.

- A procedure without waste and overspray that ensures reduced unit costs.

- A sophisticated matrix system that allows fast profile changes.

- The VACUMAT SpecialCoat® is equipped with a special internal coating. In combination with a dewpoint-controlled cooling system, the cleaning time is considerably reduced. Frequent colour changes can be executed fast.

- Self-sufficient coating management controls processing parameters and intervenes when needed to ensure optimal conditions.

- High efficiency. Depending on the workpiece, a feed speed of up to 200 m/minute can be achieved.

- Optionally, with the help of special masking tools, specific sections can be handled exclusively.

- Brilliant surfaces. Layer thicknesses from 10 to 200g/m², depending on the coating system.

- Diverse coating media are applicable, for instance, water-based coating material, UV 100% coating or water-UV coating.

- Process technology by Schiele’s founder of the VACUMAT technology – safe and reliable

- Single component coating is an optional feature.

- High production safety. The VACUMAT® is designed to run 24 hours during continuous operation.