MultiCoat

No matter if round or oval, we can coat all edges.

Customised furniture design requires nowadays turning away from standardised or linear production processes. Round, oval or kidney-shaped geometries need to be handled during edge coating as well. The VACUMAT MultiCoat exactly satisfies these requirements and thus becomes a reliable assistant in the furniture industry.

Scope of application

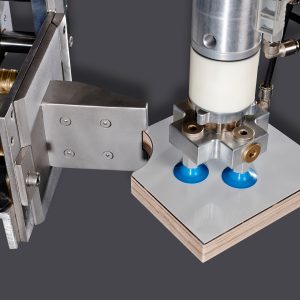

Edges of furniture, tables and all other non-linear geometries, no matter if round, oval or kidney-shaped

Performance features

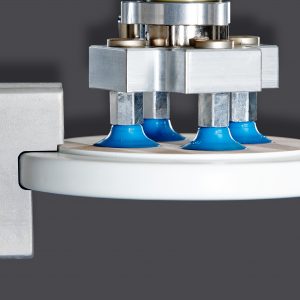

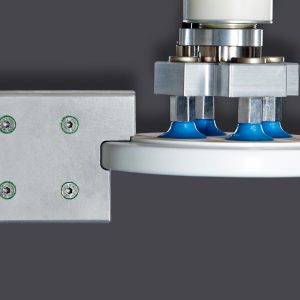

- Even edge coating at non-linear geometries.

- A procedure without waste and overspray that ensures reduced unit costs.

- A sophisticated quick-change system that allows fast tool changes.

- Self-sufficient coating management controls processing parameters and intervenes when needed to ensure optimal conditions.

- High efficiency. In particular when deploying 100% UV coating.

- The basic machine has a compact and space-saving design.

- Robot-based processing cells are individually arranged.

- Camera controlled adjustments of material tolerances are optionally possible.

- Process technology by Schiele’s founder of the VACUMAT technology – safe and reliable

- High production safety. The VACUMAT® is designed to run 24 hours during continuous operation.